Brushed or Brushless Motors?

Introductions to Brushed & Brushless Motors

Hey everyone. This is Eric Cooper.

I’m here again with some food for thought in the tools industry. It has been

several years now that brushless motors have begun to spread

through the professional tools industry and change everything to cordless

tools. What is really going on? You will face huge differences when

dealing with brushed and brushless motors. But, before we go through

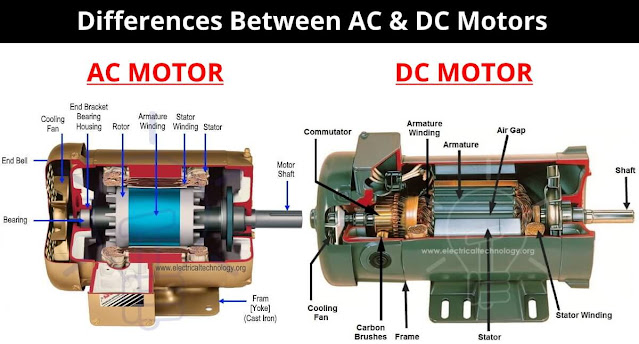

these numerous differences, let’s take a look at the fundamentals of how a DC

motor works. The first thing that comes to mind when operating a motor is all

just the magnets. The oppositely charged magnets are completely attracted to

each other. The basic observation inside a DC motor is to have a constant pull

forward by keeping the opposite charge of the rotating piece (which is the

rotor) and attracting the still magnets (which is the stator) in front of the

rotor.

There are four main parts inside a brushed motor: a ring of magnets, an armature, carbon brushes and a commutator. The brushes and magnets are stable and not moving, but the armature and commutator rotate on the shaft together inside the magnets. When the motor is filled with electricity, there is a resulted charge that travels through the brushes and goes into the commutator. After that, the commutator transfers the charge to the armature (that they are made of copper windings). These windings are magnetized by the charge and pushed against the still ring of magnets that are around it and it forces the armature to rotate. This rotation of the armature doesn’t stop until the charge and electricity flow stops.

On the other hand, the brushes and the commutator are gone when you look inside a brushless motor. Also, the place of the windings and magnets are reversed. The magnets are placed on the motor shaft and the windings of the armature (which are made of copper) are fixed and around the shaft. The amazing part in the brushless motors is that a small circuit board (instead of the brushes and the commutator) controls the energy flow delivered to the windings. In conclusion, by equipping tools with this electronic communicator, you actually have a small computer inside your power tool.

Brushed vs. Brushless, the Pros & Cons

Because of their design and

revolutionary technology, brushless motors bring

more advantages over the brushed ones. The most belong to the efficient absence

of the commutator and brushes. Because of the contact of brushes with the

commutator to deliver a charge, a lot of friction is caused. This friction

reduces speed and also brings heat to the motor. It is exactly like driving

your car by slightly pushing the brake pedal. You will add the same effort as

usual, but you will be slower. If you need the same speed, it will definitely

take more energy from the engine. This is not what happens inside a brushless

motor. Oppositely, brushless motors operate cooler and much more efficiently

so that they will be able to deliver more power.

While you use your brushed power tool, the carbon brushes wear down. It is exactly what causes a spark inside some of the tools. If you want to keep your tool working, the brushes need to be replaced with the fresh ones once in a while. In contrast, the brushless tools (or it is better to say the brushless cordless tools) do not require this maintenance.

The rotor/stator combination in

brushless motors is more compact with the help of the electronic controller. The resulted advantage is lighter weight and more

compact size with more efficient performance.

That is why we see so many power tools these days from the industrial

manufacturers that have a superior compact design and more amount of power.

You might say that brushless motors

are much more expensive to design and manufacture, but they are actually much

more efficient than the brushed motors in power tools. The main positive points

that come from them can be longer lifetime and less maintenance, more

power, and longer runtime. Brands in the market often try to go for

a balance between their tools’ power and durability in their performance. Some

of them may go after producing a more powerful tool while some others might be

interested in making power tools or cordless tools that are longer lasting. But

the newly-technological brushless tools have become powerful enough so that all

their manufacturers refer to their specifications as “corded-like

performance”. Their value is twice when they are combined with the latest

generation, high-capacity Lithium-ion batteries which are produced with the

maximum capacity of 5.0Ah these days.

Why Spending Extra on the Brushless?

The brushed DC motors

are practically simple in design and the included parts are inexpensive,

however copper is not becoming cheaper any longer. On the other hand, since brushless

motors require that electronic communicator, you will basically have

a small computer inside your cordless tool. And the result is a higher price

for the brushless motors inside a more expensive tool than other “old-school”

power and cordless tools.

Brushless for a Longer Lifetime

The combination of their advantages includes

another main effect; longer life. While all the brushed and brushless tools are

generally guaranteed to work for a considerable amount of time and under

warranty by all the brands, you can be sure to get a longer life out of your

brushless cordless models. It could even be years beyond the warranty.

Other Considerations

It isn’t true to say that brushless

motors win over brushed motors for 100 percent all the time. For

instance, moving the armature from the rotor to the stator will end to a

reduction of mass distribution of the rotor. If I want to say it in a simpler

way, the rotor in a brushless motor usually has lower amount of

inertia than the same situation in a brushed motor. What does this mean? It

means that a rotor in a brushed motor is more resistant to

rotation. So, it is not just about increasing efficiency by decreasing the

commutator frictional energy losses. Other advantages that need to be mentioned

here are improved heat dissipation, flatter torque, more output power and

reduced electrical noise.

They are expensive and it is true.

No doubt about it. They benefit the professionals better who are going to use

them every day and can afford them. Brushless tools or better

say, brushless cordless tools are somehow 30 percent more

expensive to manufacture than other cordless tools, and their batteries are

typically unavailable for most of the DIYers. But, by considering the

advancement in the technology and design of batteries, you will be seeing more

and more brushless tools at your local markets. They are designed and developed

to stay, but it will take a while until all the power tools are equipped with

this technology.

Comments

Post a Comment